When we ask tradeshow visitors who are not using Aligned Vision equipment about multitasking laser projection, the most common response we get is that their projectors have it, but they don’t use it. In theory, multitasking laser projection sounds like a valuable feature. After all, if you are able to apply one projector to multiple jobs simultaneously, or one controller to multiple projectors and jobs, this capability literally multiplies the operational value of your laser projection system. So it seems odd that floor supervisors would not take advantage of multitasking. Why is this the case?

Here is what our Aligned Vision team discovered about the problems some fabricators are having with multitasking laser projection, and how LASERGUIDE and ALIGN 4.0 overcome these problems and make multitasking a convenient and truly valuable feature – not just in theory but in practice.

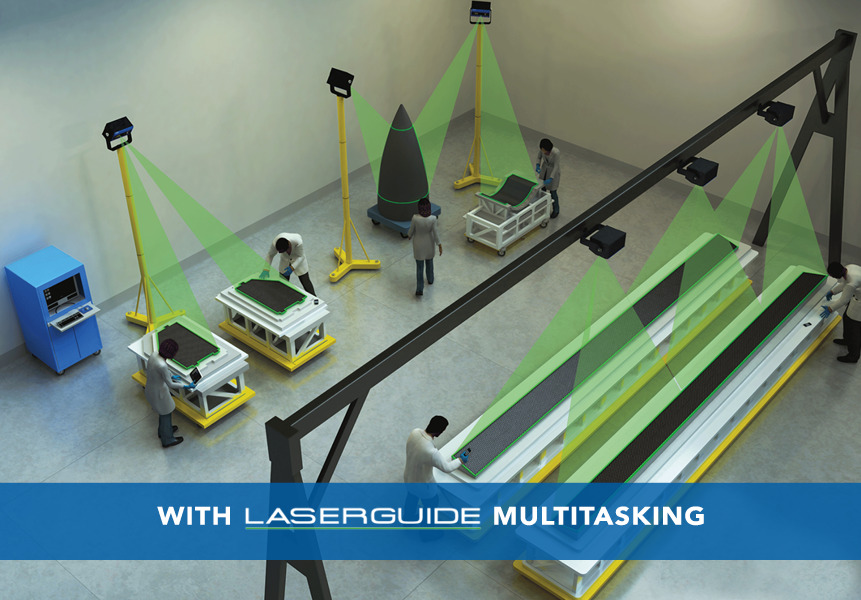

Multitasking scalability and flexibility

Two critical features of industrial software solutions are scalability and flexibility. A scalable product is able to meet growing demand for its services. Flexible software solutions are designed for seamless support of new applications. Tradeshow visitors confirmed to us that these two characteristics are essential to the usefulness of multitasking laser projection.

Scalability translates in the case of multitasking laser projection to the number of jobs actively supported at the same time by a single system made up of one controller, one seat of software and multiple projectors. The advanced engineering of each LASERGUIDE projector provides your operators with clean, clear laser projections on as many as four different tools simultaneously. A single projector within the system may be used to support four layup teams. Alternatively, each team may be assigned to multiple jobs to minimize operator downtime. While the layup on one tool undergoes vacuum debulking, for example, operators are free to lay up plies on another tool under the same projector without any startup requirements.

Maximizing value-added time is a key benefit of a multitasking laser projection system. To ensure that this benefit is not diminished by setup and alignment activities, a multitasking laser projector must also be supported by automatic registration. Without it, manual re-registration within the spatial coordinate system of each tool would increase nonvalue-added time. For LASERGUIDE, our dynamic registration suite includes the AutoAlign feature, which automatically locates targets and establishes 3D alignment.

Both scalability and flexibility are realized through LASERGUIDE’s multitasking controller and ALIGN 4.0 software. One LASERGUIDE controller supports up to eight jobs. Additionally, a single seat of our ALIGN 4.0 software manages what would require multiple seats and setups of other vendors’ software. Laser projection system flexibility enables a fleet of projectors to be configured and reconfigured at will. A multitasking laser projection solution consisting of one controller and six projectors, for example, may be used during one project to support two layups with three projectors each, and during the next project with one projector dedicated to one job, two to another and three to a third. Without this kind of flexibility, reconfiguring a set of projectors may require rewiring, repositioning, and other tedious, time-consuming nonvalue-added tasks.

Our dynamic registration suite automates alignment of reconfigured projectors through SystemAlign, a feature that automatically registers all projectors as soon as the first is registered.

Multitasking ease of use

Tradeshow visitors using other vendors’ systems frequently say that it would take too much time and effort to employ the multitasking feature of their current system. We agree! Most multitasking laser projection systems provide only one full-function user interface – the monitor and keyboard of the controller. Operators must step away from the tool, walk over to the controller and open the window for the part they are working on before they start the next step in their job. What’s more, some systems are not equipped to keep multiple jobs open at one time. This means the operator must close one part file and reopen another. If multiple teams are running jobs from the same controller, multitasking with a single user interface may even create a “traffic jam” at the controller.

Two features of a LASERGUIDE projection system overcome these difficulties and make multitasking simple to implement. First, our ALIGN 4.0 software provides easy file and job management. It enables you to display multiple part windows with modern icons and/or multiple 3D dynamic, CAD-like ply viewers. ALIGN 4.0 also supports independent steering functionality (nonmodal steer screen) for each job and other advanced functions that streamline the user experience on multiple jobs.

Second, each LASERGUIDE system provides as many as eight of your floor operators with tablets or smartphone-size touchscreen remote controls, giving them independent control of fabrication steps. Each operator stays at the tool, adding value, rather than stepping away to the controller or waiting on other operators and their jobs.

Multitasking that truly multiplies productivity

Aligned Vision first introduced multitasking laser projection in 1994, and we have continued to advance this functionality to keep up with current software capabilities, including Industry 4.0. Most laser vendors today include multitasking among the listed features for their products. As you consider new investments in laser projection, be sure to find out exactly what vendors mean when they say their systems support multitasking. We think you’ll find that LASERGUIDE continues to lead the way, helping you to make the most of your laser projection systems.