Aligned Vision has been helping companies to accelerate quality manufacturing since 1987, when we were founded as Assembly Guidance. Today, our laser guidance and smart 3D automatic inspection systems, mobile process control and digital thread technologies are empowering manufacturers to bring the benefits of digital production to their shop floors.

Our history of technology “firsts” reflects our guiding principle – to help manufacturers uncover hidden costs and then reduce or eliminate them with our assistance and expertise.

A HISTORY OF INNOVATION

WE ARE PIONEERS

Enabling composites fabricators to eliminate whole warehouses

of physical templates, accelerating quality fabrication.

1987

FIRST INDUSTRIAL

LASER TEMPLATING CONCEPT

1988

FROM PHYSICAL TEMPLATES

TO TEMPLATES OF LIGHT

1989

FIRST LASER SYSTEM DEPLOYED IN COMPOSITES FABRICATION

WE ARE INNOVATORS

Finding creative ways to maximize the payoff of new technologies for our customers

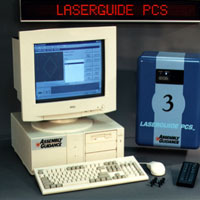

1994

FIRST SYSTEM TO GUIDE

MULTIPLE JOBS SIMULTANEOUSLY

1996

FIRST BRIGHT GREEN LASER

WITH CLASS II SAFETY

WE ARE INVESTIGATORS

Identifying and seizing opportunities to improve industrial processes

1998

FIRST ALIGNMENT CHECK THAT TOLERATES

OPERATORS BLOCKING TARGETS

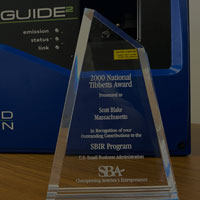

2000

NATIONAL TIBBETTS AWARD

FOR BREAKTHROUGH PROCESS CONTROL

WE ARE COLLABORATORS

Listening and joining forces with customers to bring maximum benefit from our innovations

2002

EXCLUSIVE AUTOMATIC PLY VERIFICATION (APV)

QUALIFIED TO REPLACE 2ND INSPECTOR

2005

FIRST WIRELESS, TARGETLESS,

AUTOAIM, AUTOFOCUS

LASER PROJECTOR

2010

EXCLUSIVE MULTITASKING KITGUIDE ACCELERATES ACCURATE CUTTER UNLOADING

WE ARE EMPOWERERS

Equipping our customers to make extraordinary leaps forward in their manufacturing efforts

2012

FIRST SEAMLESS

MACHINE TOOL INTEGRATION

WITH SDK

2016

FIRST MACHINE VISION/ALGORITHM-BASED

ANALYSIS REPLACES HUMAN INSPECTOR

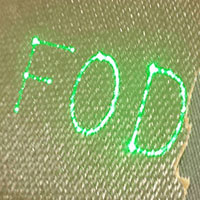

2018

FIRST FOD PREVENTION APPLICATION

IN CRITICAL BONDING

2020

FIRST APPLICATION DEVELOPMENT

FOR AUTOMATIC INSPECTION

VIA MACHINE LEARNING