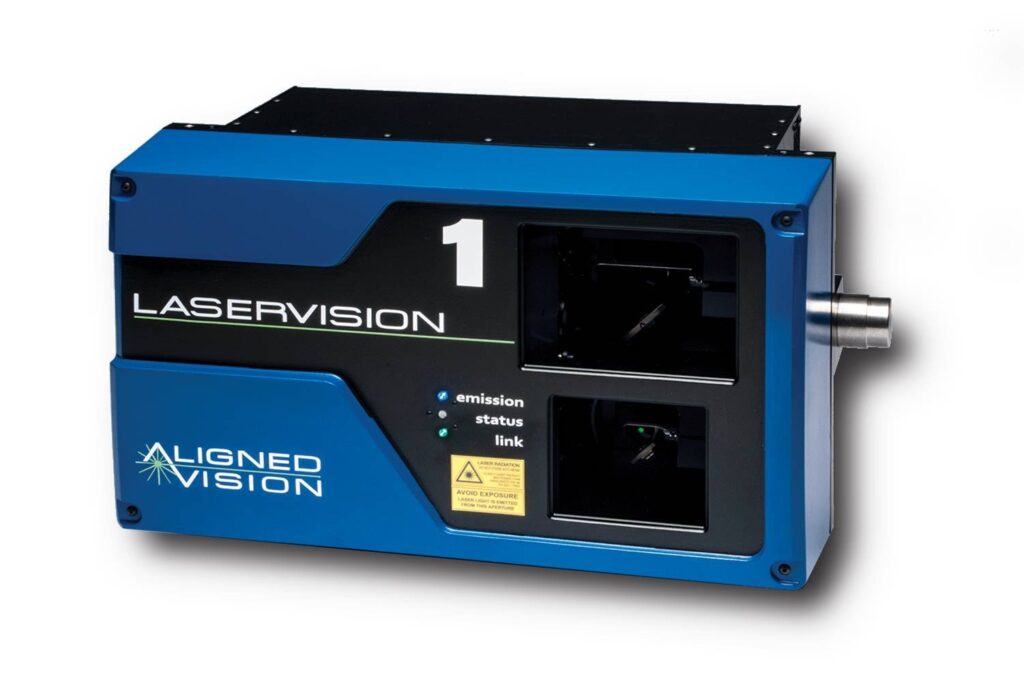

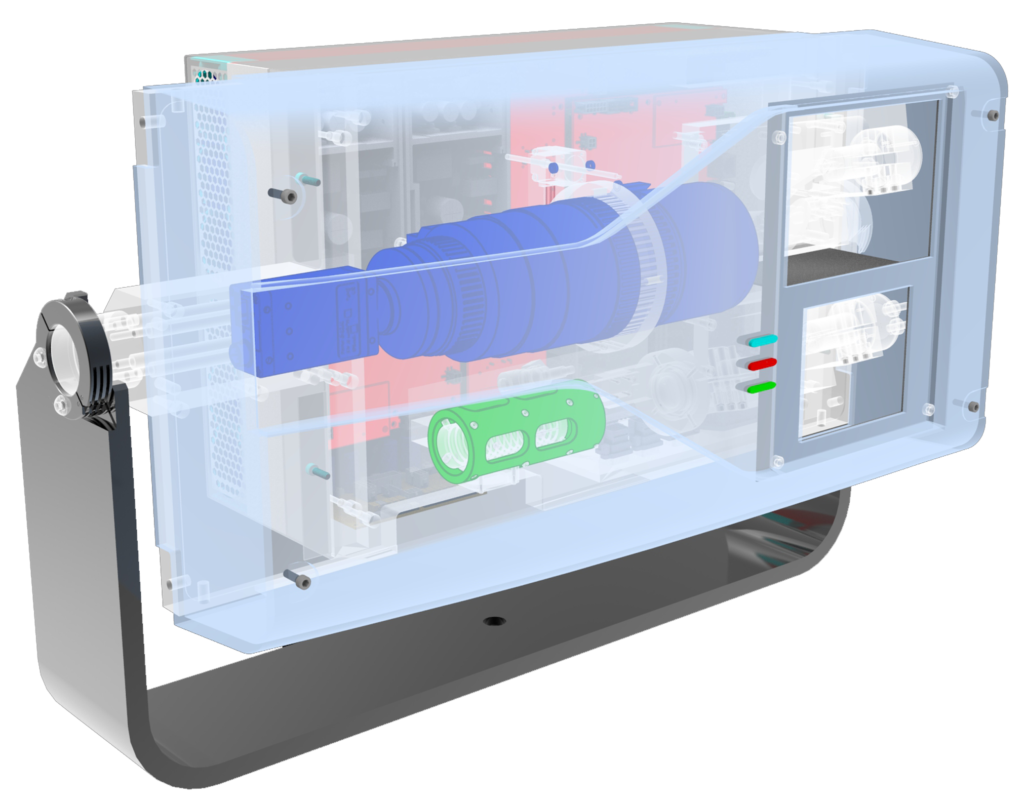

Integrating machine vision with proven 3D industrial laser projection, LASERVISION brings large-field automatic inspection to the factory floor.

WHAT IS LASERVISION?

LASERVISION provides real-time, in-process automatic inspection and real-time feedback to the shop floor. From a stationary mount, it captures detailed images of superior quality anywhere on large, complex 3D surfaces within its giant field of view (at least 10 ft by 10 ft). AI-enabled image analysis verifies and documents nearly any visible attribute, or flags it for corrective action. LASERVISION’s laser projector works like an automated version of a presenter’s pointer, directing operators to the location of any anomaly.

BOOSTING QUALITY AND SPEED, LASERVISION:

- Minimizes idle time—automatically performs an inspection when the electronic work instructions call for it

- Eliminates inspector wait time—conducts inspections in seconds with no operator or inspector intervention

- Optimizes inspection quality—uses machine vision, eliminating human distraction, fatigue and expectation bias

- Performs while production continues—stationary mount above work cell does not interfere with production equipment

- Markedly reduces rework and scrap—verifies attributes in real time and flags FOD, misaligned features (reinforcing fiber, adhesive beads), out-of-spec edge locations, excessive shear and other flaws for immediate correction

- Automatically populates electronic documentation and generates the as-built Digital Twin, including:

- Calibrated images of every WIP surface

- Any nonconformances

- Any corrective actions

- Feeds Deep Learning and closed-loop manufacturing improvements

- Quantifies uncertainty

- Enables tighter allowables and less overdesign

- Supports your team with industry-leading expertise

- AI-enabled application development

- Ongoing support for the life of your LASERVISION system from our team of experts — many with decades of industry know-how.

- Supported by our SDK software development kit:

- Integration with Automated Fiber Placement (AFP), Automated Tape Laying (ATL) and other advanced fabrication systems

- Automatic maintenance of common coordinate system

- Complete SDK: API, DLL, manual, sample code

- Instant display of any tow, course, boundary, lap or gap

Reimagined from the ground up for Industry 4.0 connectivity, our ALIGN 4.0 software maximizes the productivity and throughput of your LASERVISION system.