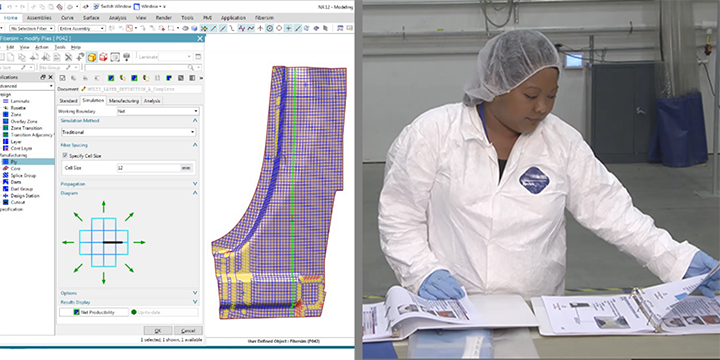

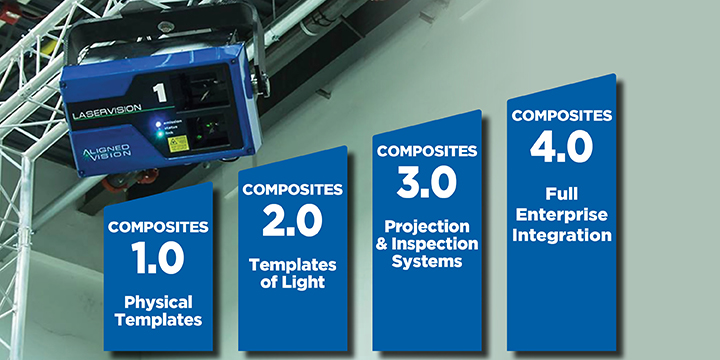

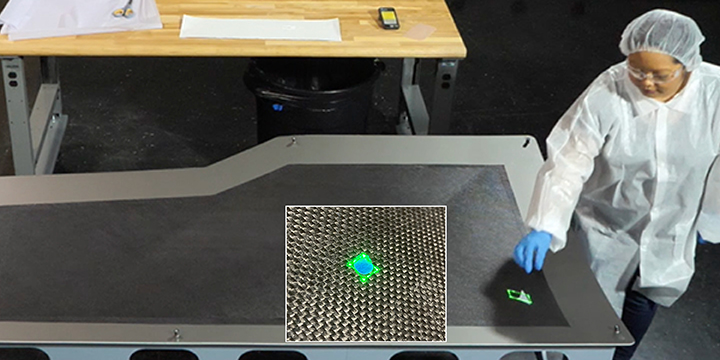

As composite manufacturing has advanced over the years, it has experienced a striking imbalance in the maturity of digital technologies. Computers have performed design and engineering tasks for decades, while paper plybooks and travelers are still used in many shops to guide composites fabrication. Since our founding in 1988 (when we were called Assembly Guidance),… Read more »