How machine vision and artificial intelligence saved an aerospace defense contractor

Zero defect manufacturing is a relatively new quality paradigm, but more and more producers of large, complex products – most notably, aircraft and automobiles – are pursuing the goal of zero defects. After the quality escapes of early 2024, which resulted in several aircraft incidents and fleet groundings, there is a growing sense of urgency to eliminate defects from the manufacturing floor. Millions or billions of dollars are at stake, as are company reputations and, more importantly, human lives.

One large aerospace manufacturing company has been ahead of the curve in zero defect manufacturing. Here is their story.

Catastrophic failures

The manufacturer became a leader in the production of large composite aerostructures in the 1990s. At that time, their only option for in-process inspection was to train highly skilled team members to manually verify critical production attributes: ply location, fiber orientation and absence of foreign object debris (FOD). This was a substantial undertaking. Inspectors had to examine each ply of an in-process composite structure that measured about 25 ft long and 2 feet wide. Rulers, magnifying glasses, flashlights and protractors were the tools of the trade.

Because these aerostructures are flight-critical, out-of-spec features are simply unacceptable. Yet the accuracy of human inspectors is inherently limited. People become distracted or fatigued. They develop a confirmation bias that causes them to see what they expect to see. These limitations cannot be eliminated by better training, shorter shifts, or spending more time on each inspection. They are particularly problematic when inspecting critical structures, where flaws occur relatively infrequently but pose a highly consequential risk to product safety and performance.

Despite their low frequency, such events do occur. The aerospace manufacturer’s business was placed in jeopardy when external quality escapes resulted in two catastrophic failures caused by incorrect fiber orientation within the structure. In each case, the aerostructure broke apart, causing severe aerodynamic instability. Pieces of the aerostructure dangerously flew off the aircraft. Only by good fortune did the incidents not lead to loss of life or result in complete loss of the aircraft.

Replacing a second inspector with automatic ply verification

Around the time of the aerospace company’s two quality escapes and catastrophic failures, Aligned Vision was developing a machine vision-based inspection system under a U.S. Air Force Small Business Innovation Research (SBIR) grant. The SBIR demonstration system successfully captured calibrated images of laid up plies and measured fiber orientation with consistently high accuracy.

The aerospace company authorized Aligned Vision to develop a solution to their problem based on the SBIR demonstrator. The result was automatic ply verification (APV), a machine vision technology that automatically inspected the aerostructure as it was laid up. Layup operators, who conducted the first inspection, no longer had to wait on a second inspection by a designated inspector. Instead, the laser projection system would cast an outline on the aerostructure work-in-progress (WIP) where the layup operator would place a handheld APV device. The calibrated images captured by the APV would be automatically analyzed by a computer algorithm, and the system would either verify correct fiber orientation or stop projecting ply locations and alert the operator to the failed ply. The operator would be able to correct any defects before they were covered by the next ply, at a point in production where the time, effort and cost of correction were lowest.

Working with Aligned Vision and a designated Federal Aviation Administration (FAA) inspector, the aerospace company was able to fully qualify APV for verification and documentation of flight-critical characteristics of the aerostructure, including fiber orientation. In 2002, the FAA qualilfied APV to replace the second human inspector.

Applying APV to in-process inspection of thousands of aerostructures between then and 2020, the aerospace company experienced zero quality escapes. In several instances, the APV detected an out-of-spec fiber orientation that the human inspector had overlooked. This was corrected before an escape into field service occurred, also reducing the time and cost of rework.

AI-driven large-field automatic inspection achieves six sigma

In 2020, the aerospace company transitioned to LASERVISION for automatic in-process inspection of its large aerostructures. While APV pioneered machine vision-based inspection, LASERVISION has advanced the technology with several industry “firsts”:

- A giant field of view (6-25 m2) captures detailed attributes and anomalies within the entire aerostructure.

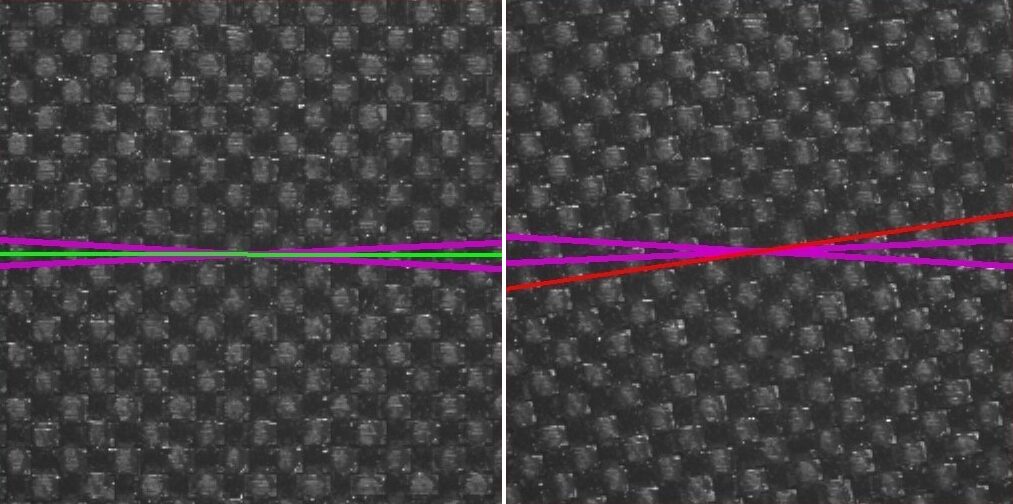

- Ultra-high resolution images capture surface features nearly invisible to the human eye.

- AI-driven image analysis achieves near-100% inspection accuracy.

- A large standoff distance allows automatic inspection to occur without disrupting production operations.

- Automatic documentation electronically records both data and calibrated images.

- The system is able to stitch captured images together, producing single images of entire ply surfaces.

In 2022 as part of its quality program, the aerospace company asked Aligned Vision to demonstrate six sigma reliability of LASERVISION. We investigated the likelihood of a “false positive,” in which fiber orientation is actually out of spec but the system verifies correct orientation and allows the operator to continue building the part. We found the probability of a false positive to be 1 in 2.5 billion (99.9999996% reliability), a performance far beyond the six sigma standard of 3.4 in 1 million (99.99966% reliability).

This LASERVISION user is benefiting not only from extremely high confidence that the part is built as designed, but also from much lower inspection time, and therefore, shorter fabrication cycle time. LASERVISION has cut inspection time by 80% over APV and by more than 95% compared to manual inspection.

While the proving ground for LASERVISION has been in-process inspection of large composite aerostructures, the technology and engineering principles behind it have been demonstrated on large, complex components and assemblies manufactured by a variety of industries for a broad range of applications. Aligned Vision is helping new customers not only to implement LASERVISION but also to navigate the qualification process. Importantly, LASERVISION is easily installed to operate in the background and gather data for qualification while you continue running your already-qualified inspection processes.

If you are seeking to achieve zero defect manufacturing and benefit from comprehensive Quality 4.0 data at your facility, let’s discuss how to apply large-field automatic inspection on your shop floor. Contact us today for an onsite or online demonstration of LASERVISION